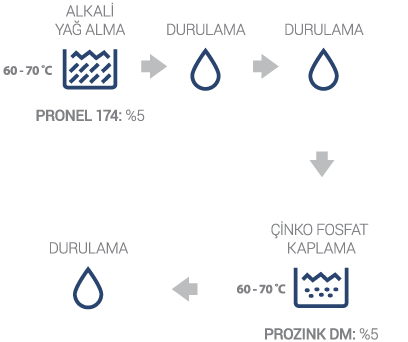

Calcium-Modified Zinc Phosphate Process

- DOES NOT PRODUCE SLUDGE.

- SINGLE MATERIAL.

- STABLE.

- Unlike conventional zinc phosphate baths, it does not produce sludge.

- Provides ease of operation.

- No powdering occurs on coated metals.

- Setup and additions are made with a single chemical.

- Does not require auxiliary chemicals such as accelerators, pH adjusters, or activation agents.

- Bath controls are easy.

- Setup cost is low.

- From the moment the bath is set up, it forms a homogeneous, smooth microcrystalline coating.

FREQUENTLY ASKED QUESTIONS

In classic zinc phosphate baths, iron precipitates as sludge. In the calcium-modified zinc phosphate bath, iron is dissolved and removed by strong oxidizers, so no sludge forms in the bath. Thus, problems caused by sludge are eliminated.

No, deionized water is not required.

Yes, it can be used. When a degreasing chemical suitable for spray processes is selected, it can be used on spray lines.