Galvanized Surface Treatment Process

- FEATURES.

- Galvanized surfaces are bright and smooth surfaces. To ensure paint adhesion, the surfaces need to be roughened.

- Phosphating alone is not sufficient for this process. The chemicals used for this purpose etch the surface and prepare it for painting.

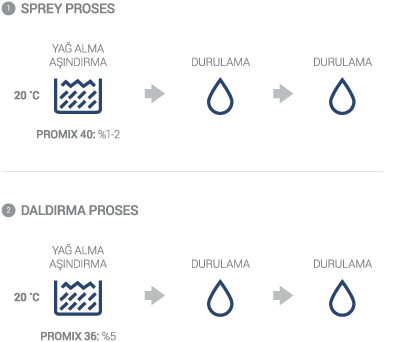

- This process can be carried out by dipping or spraying, and in the case of very large parts, it can also be done by wiping or brushing. The process operates at room temperature.

FREQUENTLY ASKED QUESTIONS

A minimal etching (1–2 µ) is performed at a level that allows paint adhesion. This etching can be observed visually as a dulling of the shiny galvanized surface.

Yes, the process also has oxide cleaning capability.

A processing time of 1–3 minutes is sufficient. Yes, it can also be applied by brushing on flat surfaces.