Nanotechnology Coating Process

- FAST.

- COLD.

- ECO-FRIENDLY.

- HIGH PERFORMANCE.

- PRACTICAL.

- Short processing time.

- Fewer baths.

- Increases production speed.

- Operates at room temperature.

- Saves energy.

- Does not contain heavy metals.

- No sludge forms in the bath.

- Does not contain phosphate, volatile organic compounds, or regulated chemicals.

- Enhanced corrosion resistance.

- Salt spray test results up to 700 hours.

- Easy to control the process.

- Does not require deionized water.

- Suitable for iron-steel, galvanized, and aluminum surfaces.

FREQUENTLY ASKED QUESTIONS

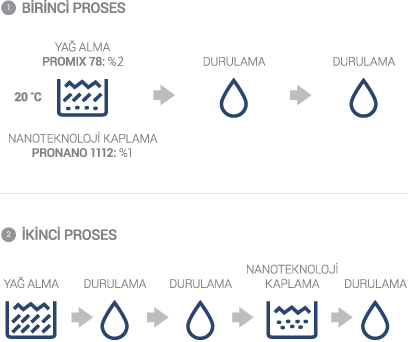

The first process is a short one in which degreasing and coating are done in the same bath. It is suitable and more practical for slightly oily surfaces. It takes up less space. If oilier surfaces are involved, the second process should be preferred. This way, the coating bath does not become dirty quickly and lasts longer.

Yes, it is possible. However, it must be replaced more frequently compared to the process that includes rinsing. Because when the bath gets dirty, there won’t be any rinsing step to clean off potential impurities left on the surface.