Wasteless Pro: Waste-Free Surface Treatment Process

- WASTELESS.

- ENVIRONMENTALLY FRIENDLY.

- OPERATES AT ROOM TEMPERATURE.

- SINGLE STAGE.

- HIGH PERFORMANCE.

- NO WATER IS USED IN THE SYSTEM.

- SAVES WATER AND ENERGY.

- AVERAGE 20 m2 SURFACE TREATMENT WITH 1 KG OF CHEMICAL.

- INNOVATIVE.

- There is no wastewater in the system, no sludge is formed.

- It does not require an EIA Report as it has no solid, liquid, or gas waste.

- Does not contain chlorofluorocarbons (CFC) or hazardous air pollutants (HAP).

- Does not contain heavy metals.

- No heating is required.

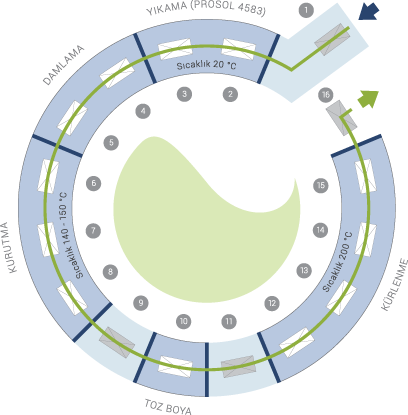

- There is a single chemical operation and a single bath in the system.

- Salt spray resistance up to 500 hours with epoxy and epoxy-polyester paints.

- The process does not include stages that require water usage such as washing or rinsing.

- Since no water is used and it operates cold, it ensures maximum savings.

- Consumption may vary between 15 - 25 m2 depending on the geometric shape of the parts.

- Completely different from traditional systems. The chemical bath is never discarded.

- Only the missing amount is added.

FREQUENTLY ASKED QUESTIONS

Although resistance is high with epoxy and epoxy-polyester paints (500-600 hours salt spray), some weaknesses may occur in polyester paints if they do not contain TGIC.

An average processing time of 1 minute is sufficient.

Oil does not accumulate because the polymer in the chemical absorbs the oil, transforms it into a structure that adds flexibility to the coating, and uses it in the coating.

Analyses and controls are performed by our technical team. Unlike water-based baths, it does not require daily analysis.